Brown Rice

Rice is one of the most important factors in determining the quality of sake. The fundamental of sake brewing is to select the most precise kind of rice for sake and polish them. We consider this process critical at Houraisen so we polish our own rice here.

There are mainly 2 types of rice that are grown in Japan, one is “Uruchi rice” and the other is “Mochi rice”. For sake brewing, “Uruchi rice” is used. However, there are sometimes that “Mochi rice” is used for sake brewing. Since Mochi rice has a mild sweetness to its flavor, there is a process called “Mochi rice 4 step” for making sweet sake by adding saccharified Mochi rice to the last period of Moromi. There are 2 kinds of Uruchi rice, one is the normal rice for eating, and the other is rice for brewing sake, which is the main ingredient of sake. There are various kinds of rice for sake brewing. Some of the famous one is Yamadanishiki, Miyamanishiki, Gohyakumangoku, Omachi, Wataribune, and Hattannishiki.

The difference between Sake rice and Normal eating rice

There are mainly 3 differences between sake rice and normal eating rice

There is a clear Shinpaku (white core) in the middle.

The process of growing Shinpaku in rice is to grow in optimal conditions. When the rice grows large, the starch cannot fill the middle and creates portion that is coarse in density. This appears as Shinpaku. If there is Shinpaku inside of rice, the structure allows the Koji mold to enter the middle of the rice easier, and becomes Koji with good Hazegomi. Sometime, people misunderstand that “Bigger the Shinpaku is, the better the rice”. If Shinpaku is too big, it gets broken while being polished. In order to endure the polishing, it is best to have a Shinpaku type called Spotted Shinpaku. Actually, Yamadanishiki, which is called the King of Sake rice, has may rice bits with Shinpaku in spots and lines.

The rice is large and uniformed in size.

If the rice is bigger, it is easier to polish, and easier to process as ingredient such as washing and steaming. Also, it is important that the rice is uniformed in size because if there is difference in size, it varies the size of white rice causing vary in absorption and fermentation.

It contains little protein and fat.

Since protein and fat cause offset in flavor and cause odor, the sugar layer which contains large amount of protein and fat is polished off during polishing. Although it is polished off, the amount of protein and fat contained in brown rice affects the amount of protein and fat contained in white rice. So it is better to have small amount of protein and fat in the brown rice.

White Rice

When rice is polished, it is smaller because the center is left while the outside is polished off (the picture on the left is 40% polished). Good tasting sake is made only with the rice center because the outside of rice causes an offset in taste.

The rice is polished in a polishing machine by passing by the rotation cylinder of polishing stones called roll and polished bit by bit. However, if the speed (rotation) of polishing stone and the amount of rice passing through is not controlled properly, it may break or smash the rice and rice cannot be polished appropriately. Normally,more polished rice must be polished with slower rotation. However, it does not mean that as the polishing ratio increase proportionately. It increases progressively such as 12 hours for 60%, 24 hours for 50%, 72 hours for 40%, and 100 hours for 35%. In reality, we cannot stay with the machine the whole time the rice is polished, so most of the breweries that polish their own rice have polishing machines that can control the rotation and the amount of rice automatically. Also, rice polishing costs a large amount of money because of the cost of the machines and facilities, labor costs, and hardness of the labor. So most of the breweries are commissioning rice polishing using Agricultural Cooperative, rice polishing company or a communal facility.

Why is rice polished?

In sake fermentation, it promotes the activity of Koji bacteria and yeast too much if there is a large amount of protein, fat, and ash. It makes it difficult to control them. Also, protein offsets the flavor and fat causes odor. Therefore, it is necessary to eliminate the rice bran (brown portion) which contains a large amount of protein and fat. Polishing is the process to do it. However, they are not only contained in the layer of rice bran, but also in outer surface of the starch inside (white portion). Therefore, sake brewing must polish the rice down to 70% for the Kasen class. In comparison, eating rice is only polished 5% of the whole rice. If it is Daiginjo class, it is necessary to polish it to the pure starch portion, so it is not rare to polish it down to 35%.

Polishing ratio and Actual polishing ratio.

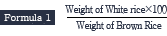

Often times, it says “Polishing ratio ○%” on labels. It normally means apparent polishing ratio, and can be calculated by the formula (1). For example, if 1000kg of brown rice turns into 600kg of polished rice, it means that it is 60%. However, this formula is not considering the broken and smashed rice which is eliminated as rice bran. In order to evaluate the true quality of polishing, the actual polishing ratio is calculated by formula (2). This will show how much of the rice is actually polished.

It is important to evaluate the quality of the polished rice by various aspects not only the actual polishing ratio , but also by grain weight which shows the evenness in rice sizes, and analysis of the protein

Washing and Soaking

Polished rice is washed well (washing), and soaked at the same time in the amount of water for the desired purposes and left it overnight.

Since the white rice is dry right after polishing, it will break if it is washed right away by absorbing a large amount of water. So normally the polished white rice is not used right away, but waits for two weeks during the period of “Karashi” in order to get the moisture back to the natural state. It is necessary to have the rice absorb water before steaming. However, before steaming, the white rice is washed to eliminate rice bran. We must be cautious not to put too much impact on the rice and break the rice when washing. Recently there are some machines that wash rice with bubbles (like Jacuzzi bath washing rice with water and air). After that, the rice is soaked in water (until it absorbs the optimal amount). Since highly polished rice absorbs water quickly so the soaking time must be controlled down to the second. It is called limited water absorption.

Steaming Rice

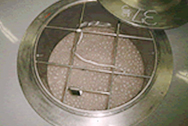

At Houraisen, we use Koshiki to steam the washed and soaked rice. It is the same principle as the traditional Wagama for steaming rice. This makes the ideal steamed rice which has soft inners and hard outer. The picture shows cooling process. Cooling is done in order to bring down the temperature of the steamed rice to the desired temperature.

When sake is brewed, the rice is normally steamed in order to make it α form. However, rice is cooked in some brewing methods, and they are called “Yumaizukuri” and “Himeiizukuri”. Although, the water content percentage is about the same whether it is steamed or cooked, when the rice is cooked, it has the advantages that ; (1) it is not sticky on the surface so it is easy to handle because it will not stick on the tools and hands, (2)it is easier for the koji mold to grow on it.There are 2 machines to steam rice; Koshiki and Continuous rice steamer. The principle is the same for both, but the mechanism is different. Koshiki has the same mechanism as a steamer for shaomais and steamed bums where one batch is steamed at a time. On the other hand, a continuous rice steamer carries the rice on a conveyer and steam is sprayed on to heat the rice. Although both have advantages, Koshiki cannot process continuously so it is not very efficient, but the steam can be controlled in detail so the quality of steamed rice is good. On the other hand, it is difficult to control the steam in Continuous Rice Steamer, but it can efficiently process a large amount of rice.. The steamed rice is cooled down to the optimal temperature, and is used for Koji, Shubo, and Moromi. There are natural cooling methods where rice is spread on a cloth, and enforced cooling method where the air is blown through the layer of rice.

Kojimai

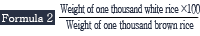

Kojimai is made by planting Koji bacteria on the steamed rice and it is then cultivated for about 50 hours in a special room called Koji room where the temperature and moisture is controlled. Koji is the most important process in sake brewing because it changes the starch contained in rice into glucose (sugar).

Koji is made by planting and growing Tanekoji (Kikoji spours) in steamed rice. Koji’s main role is to make various enzymes and use them to increase the fermentation process of Moromi. Enzymes contained in Koji include diastatic enzyme (glucoamylase) which promote saccharification of starch, liquefying amylase (α-amylase) which promote liquidation of rice, and protease which break down protein and create amino acid.

How to make Koji

Hikikomi

Steamed rice is carried to Koji room and spread on Toko (a stand where Koji bacteria is cultured on the first day of koji making), and treated by hand until the temperature and moisture is appropriate.

Tanetsuke

When the temperature and moisture of the steamed rice is in an appropriate condition, Tanekoji is spread evenly. This process is also called “Itamomi”. After this process is finished, the steamed rice is bunched up and wrapped in cloth. After this, a process called “Kirikaeshi” is performed once before Mori. It is to break down and mix up the steamed rice to prevent the rice from sticking together or prevent the variance in temperature and moisture.

Mori

About 24 hours after the bacteria is planted, it increases to the point where we can see the white spots with our naked eyes. After this, Koji is moved to containers called Kojibuta or Kojibako, where it is easier to control the temperature.

Nakashigoto, Shimaishigoto

Koji is finished 24 hours after Mori. However, the processes called Nakashigoto and Shimaishigoto are performed in order to cool down the heat caused by the fermentation, and supplement the oxygen that the bacteria consumes. By gradually drying the Koji during this process, Koji bacteria extend its mycelium to the center. So temperature and moisture control is critical during this process.

Dekoji

Koji is finished 24 hours after Mori (48 hours after Hikikomi). The temperature is brought up to 40 to 42 ℃ in the end. The finished Koji is taken out from the warm Koji room and spread out on a stand to cool down. While it is cooling down, it gets stirred a few times so it is cooled down evenly and there is no variance in temperature.

Shubo

Shubo is a process where the yeast, which has the main role in sake brewing, is cultivated up to a certain amount. The yeast makes the alcohol from the glucose that Koji makes. At Sekiya Brewery, we make Shubo in about 2 weeks with the process called Fast Fermenting Process. It is one of the most important processes that can change the fermentation of sake.

In sake brewing, it is necessary to have Koji, which convert starch into glucose, and yeast, which convert glucose into alcohol. The process to cultivate the yeast (high grade yeast) up to a certain amount is called Shubo Making.

In Shubo Making, it is essential to have “lactic acid” which suppresses the growth of bacteria that causes spoilage such as wild yeast. The Shubo that was made from the activity of lactic acid bacteria from lactic acid is called “Kimoto Shubo group”, and Shubo made by adding brewing lactic acid is called “Fast fermentation Shubo group”. There are “Kimoto” and “Yamahai Shubo” in Kimoto Shubo group. There are “Fast fermenting Shubo” and “High Temperature Saccharification Shubo” in the Fast fermentation Shubo group”.

Moromi

Shubo is then transferred into the tank and water, Kojimai, and steamed rice is added three times for preparation (3 step preparation). In Moromi, saccharification of starch by Koji, and glucose fermentation to alcohol by Shubo are taking place simultaneously (multiple parallel fermentation). The fermentation condition is always monitored from the taste and the surface condition. The fermentation is controlled in order to brew sake with the desired quality.

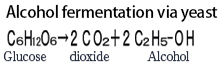

Moromis is made by mixing a determined amount of steamed rice, koji, shubo, and water and getting the mixture fermented. During this process, fermentation (chemical reaction) shown in the figure on the right is taking place simultaneously. It is called multiple- parallel fermentation, and this form of fermentation is rare among the world’s brewing process.

Wine is made with “single fermentation” where only the sugar contained in grapes is fermented. On the other hand, in beer fermentation, saccharification of barely and alcohol fermentation of sugar takes place separately, and this fermentation process is called “simultaneous saccharification and fermentation”.

Compared to these, the fermentation taking place in Moromi of sake is a complex process that is one of a kind in the world. It is a world class fermentation technique of Japan.

About preparing Moromi

Moromis consists of koji, steamed rice, and water added to shubo. When that is fermented and pressed, it becomes sake.

Moromi is usually prepared in 3 steps over 4 days, the preparation is called “three step preparation. The first day is called “Soejikomi” which is the first preparation, the second day is called “Odori” and there no preparation that day, the third day is called “Nakajikomi” which is the second preparation, and the 4th day is called “Tomejikomi” which is the last preparation. Also, the 4th day is the first day of Moromi.

MMoromi is finished in 25 to 40 days. Moromi shows various Tura (translated “face” meaning the surface such as bubbles). It is a critical job of Toji to determine the temperature control while considering the appearance, taste and the results of composition analysis. Lastly, the Moromi is pressed and becomes sake.

Soejikomi, Odori

About 1/6 of the koji and water is added to the yeast, and 1/6 of the steamed rice is added while being stirred. It will increase the yeast by resting the next day (Odori).

Nakajikomi

The day after Odori, 1/3 of Koji and water is added, and 1/3 of steamed rice is added while being stirred.

Tomejikomi

The day after Nakajikomi, 1/2 (the rest) of the koji and water is added and the rest of the steamed rice is added while being stirred.

Sujiawa (about the third day)

The bubbles are streaking the surface of the Moromi. It shows that the yeast have started the fermentation. It is also called “Kaniawa”

Mizuawa (about the 7th day)

The white light bubbles are spreading across the surface. It is called Mizuawa.

Iwaawa (about the 8th day)

After Mizuawa, the bubbles get thicker and starting to look like rocks. So those are called “Iwaawa” (rock bubbles)

Takaawa(about the 10th day)

When Iwaawa rise even higher, it is called Takaawa. Since large amount of yeast is contained in the bubble, they prevent the bubbles from spilling by performing a process called “Awakeshi” (popping bubbles).

Ochiawa (about the 11th day)

When it is past Takaawa, the bubbles drop significantly in about one day. It is called Ochiawa.

Tamaawa (about the 13th day)

After the bubbles drops, pretty bubbles similar to soap bubbles appear on the surface of Moromi. It is called Tamaawa.

Chirimenawa (after about 15th day)

After Tamaawa, the fermentation slows down and carbon dioxide produced by fermentation also decreases. The small bubbles that appears on the surface during this period is called Chirimenawa

Bozu (after about 18th day)

There is barely any fermentation during the last period of Moromi, so there are hardly any bubbles. This state is called “Ji”or“Bozu”.

Right before Joso (about the 30th day)

Right before Joso (pressing) all the yeast dies out from the alcohol they produced. Sometimes dead yeast and rice scraps float on the surface. It is called Futa (lid).

Joso / Sake less

Moromi is finished in 25 to 40 days. Then, it is separated into sake and sake less by Joso (pressing). More carefully brewed sake has more sake less. At our company, our Daiginjo class leaves about half of the rice that was used for brewing as sake less (normally, 10 to 20% becomes sake less). Fresh pressed sake contains carbon dioxide and rice bits called Ori, and taste wild and fresh.

Peeling off the less

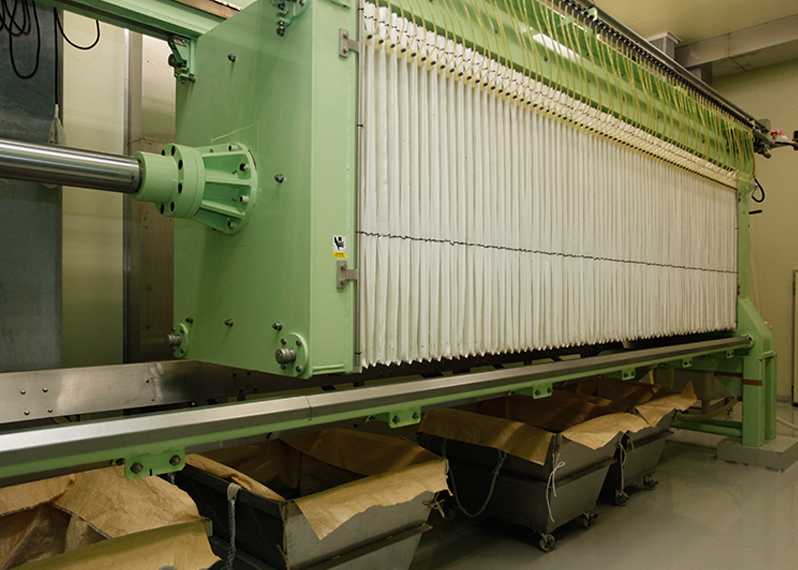

The process to separate Moromi into sake and sake less is called “Joso” and there are various methods. Normally, the method called “Yabuta (the name of the manufacturer that makes the machine)” that can press large amounts of Moromi is used. The method that presses a lesser amount is called “Fune”. The method that presses the smallest amount for contests is called “Fukuroturi (Kubitsuri)”.

It is critical to pay attention to the sanitary conditions such as cleansing, sanitizing, and drying the machines, filter cloths (cloth for filtering sake) and sake bags, and cooling and moisture of the process rooms in any method of pressing. Also, since it is called “sake” if Moromi is filtered so “Nigorizake” which is filtered with loose filter is also included in “sake”.

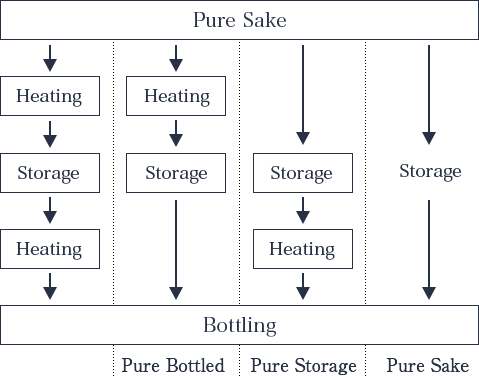

Sake(Pure Sake) / Heating

Pressed sake is filtered in order to eliminate Ori. All fresh sake is pure sake. Although it is very little, pure sake is still fermenting, so it is heated up in order to stop the fermentation if necessary. Heating up is also effective in killing bacteria that causes spoilage while being stored.

When sake is freshly pressed, it is naturally still pure sake so there is some yeast still alive and enzymes that aided in Moromi fermentation. This will be bottled through various processes. Depending on the process performed between pure sake to bottling, it is called different names.

Stored, Matured

Sake is stored in storage tanks until it is ready to ship. The storage period is about a half year for the short ones, and about 3 years for the long ones.

Low temperature maturing gets rid of the hardness and roughness and makes the sake deep and mild in flavor.

Bottling / Finished product, Delivering

Finally, this is the last process. The bottled sake is stored in a cool storage and delivered to the liquor store near you. At Houraisen, we think that it is important to control the temperature not only during the brewing process but also for the finished product until the delivery.

Traditional Sake Brewing Skills with New Technologoes

At Sekiya Brewery, we consider three things necessary for “sake brewing”; first is to “carefully make the blueprint”, the second is “to perform the process carefully and precisely”, and the third is “the teamwork among the brewers”.

You may think of industrial products when you hear the word “blueprint”. However, we need blueprints for sake brewing too. We start thinking things like “what kind of customer is going to drink this in what situation?” and “what kind of flavor should it have?” Then we have to decide how much rice to polish, select the yeast and Koji, and think about the fermentation process, and maturity process in order to express the flavor or the concept. That whole plan is the blueprint of sake brewing.

If we prepare sake without a good blueprint, the sake is merely done. We think that sake is something to be “created” instead of “being done”

It is needless to explain about the second one. Sake brewing starts with rice polishing and there are many processes. If there are mistakes and slacking in each process, there will be “deductions” every time. If the possible 100 points that the rice have is deducted by 5 and 10 every time there is a mistake in a process, there may be nothing left in the end. In order to prevent it, we try our best to perform carefully and precisely. However, it is extremely difficult to pay close attention to all the processes.

We must perform the ingredient processing carefully from polishing rice to steaming and we also have to pay close attention to the temperature management during the processes dealing with Koji, Shubo, and Moromi, and filtering and blending before bottling. In order to pay close attention to those processes, we implemented machine processing and computer management for temperatures.

Also, another advantage of mechanization is that the machines do not work differently whether it is Junmai Daiginjo or Honjozo. If the brewers are measuring the temperature by hand, they cannot perform the perfect temperature management throughout the half year of sake brewing for every Koji, Shubo and Moromi. In order to concentrate on the Daiginjo, it is necessary to do less for the Honjozo. Also, as long as they are people, they have to sleep and sometimes they do not feel well. Although it is natural, the external conditions such as temperature and moisture are not consistent. In order not to let those factors affect the sake brewing, mechanization is essential.

The third factor, teamwork, is also important. There is a word in sake brewing called “Wajoryoshu” It means that harmony will brew good sake or good teamwork of the brewers will brew good sake. As you know, sake brewing is division of labor. Sake is made by many different brewers such as the brewers in charge of ingredient processing, the brewers in charge of Koji, the brewers in charge of Shubo, the brewers in charge of Moromi and so on. If they all do their jobs as they please, the flavor of the sake will be disjointed. We believe that we can make wonderful sake that can electrify people only by sharing the blueprint of sake, sharing the workmanship of the rice, and sharing their fermentation among all brewers.

In order to improve teamwork, it is necessary for each brewer to improve their skills. For that purpose, we built Ginjo Workshop in Toyota city (old Inabucho) to pass down the sake brewer’s skills to the younger brewers. If we do not do that, we cannot improve the team skills or pass down the sake brewing skill to the future generations.

There is another meaning for “Wajoryoshu”. It means “good sake will cultivate harmony” or it creates harmony when you get together with your friends and drink good sake. What we consider good sake is sake that has good and sweet flavor of rice and also have softness and great harmony of scent. We hope that we can keep brewing sake like that.

And we also aim to brew sake that only Sekiya Brewery can brew…

Sekiya Brewery Co., Ltd.

7th Brewery Owner, Ken Sekiya

Daily Development

This is Takanobu Arakawa, the head brewer of the main company factory.

In the main company factory, a large portion of many processes are being mechanized. Even when the machine is high quality, it is the people who use it. Without the experience and skills we cannot fully utilize the functions or cannot control the process of fermentation. We would like to keep brewing good sake using the machines as tools instead of being used by the machines with a motto of Daily Development.

I am proud of being the head of brewer of the main company factory of Sekiya Brewery, and want to provide sake that people enjoy.

Brewing sake, seeing the face of each other

I am Naoya Miyase, a Toji, the chief brewer of Ginjo Kobo.I am Naoya Miyase, a Toji, the chief brewer of Ginjo Kobo.My motto of brewing sake is that we, I and customers of my brewery, are able to see the face of each other to feel close with the distance of our hearts.The total amount of custom-made sake brewing is 60kg, conversion of polished white rice. I hear the requests of each customer, and then I produce each different type of sake. It is one of the characteristics of Ginjo workshop that to brew many kinds of small amount of sake by handcrafted work.I always respect my customers’ taste for sake, and their particular about it, which I can’t measure by numerical value. I take account of them for brewing the sake, having the background story. I cherish close communications with my customers to brewing sake that are charged with their feelings, and also, I tell them how wonderful fermentation is.I try to satisfy all my customers by day-by-day efforts.